HIGH-PRESSURE PRODUCT

High Pressure Equipment Company (HiP) holds ISO 9001 certification in USA, underscoring our commitment to quality. We proudly serve as a preferred supplier across a spectrum of industries, including waterjet cutting and cleaning, oil and gas, chemical and petrochemical, as well as in research and development, and general industry sectors.

Years of Trust in Viet Nam: PPSC, Your Reliable HIP Distributor

High Pressure Equipment Company:

HiP is a leader in the production of components and pumps for industries with high pressure applications.

Official distributor in Vietnam:

Pacific Pressure Systems & Component Co., ltd (PPSC) is currently cooperating as well as being the official distributor.

Access high quality products:

Being an authorized distributor allows us to provide our customers with access to the best hydraulic and high pressure products on the market.

Quality assurance:

You can rest assured of top quality SPIR STAR products, backed by our unwavering dedication to customer satisfaction and outstanding service.

MAIN PRODUCT

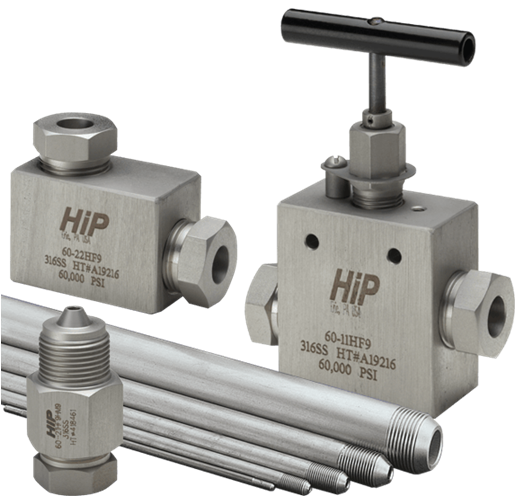

Valve, Fitting, Tubing

High-Pressure Pump

Pump System

Product Feature

High Pressure Equipment Company has developed a line of Ultra High Pressure products to assure safe and easy plumbing from 10,000 psi to 150,000 psi. These needle valves, fittings, check valves, tubing and nipples are engineered to the highest standards of repeatable quality. The reliable performance of these products has made HiP one of the world's leading suppliers of elevated pressure components.

System on request

HiP offers a range of standard power packs that are typically in-stock or available with a short lead time, as well as custom power systems to satisfy your specific requirements. All HiP power systems are factory pressure tested prior to shipping.

Application for Industry

The extensive range of products offered by the company is meticulously crafted and tailored to meet the specific requirements of diverse industries. Through a commitment to precision engineering and cutting-edge manufacturing processes, each product is uniquely designed to cater to a variety of applications across various sectors.

High pressure testing applications including but not limited to BOP Stacks, choke and kill lines, Christmas trees, valves, pipelines, hoses, cylinders, pressure vessels and components, valve actuation and any other type of equipment requiring high-pressure static testing. The test units may be provided in working pressure ranges up to 150,000 PSI and are safely tested with its compact easy to operate and friendly control panel design.

HiP has been in the forefront of providing high pressure valves, fittings and tubing to support our customers as they incorporate hydrogen in their zero-carbon energy strategies. The ongoing build-out of the hydrogen refueling infrastructure necessary to support the fuel cell powered trucks, buses, cars, forklifts and other equipment depends on products designed and built to meet the unique challenges of hydrogen.

HiP components are produced in a strict production line as well as provided with certificates of anti-corrosion quality in chemical-related applications such as transporting crude oil, pumping chemicals into tanks.

With a pressure of up to 150,000 psi, HiP components are widely used in spraying, removing paint from surfaces, cleaning large pipes, cleaning tanks, and cold cutting pipes.

The Sprague air driven pump offers economical advantages for the pressure testing of hoses, pipes, valves, fittings and other hydraulic vessels and products. The time saving and performance advantages offered by these pumps allow routine production testing to be converted from tedious hand-pump methods to automatic and precision testing methods.